Re/genT is a manufacturer of test rigs and test facilities, tailor made, for companies all over the world.

Of course, before an actual test facility of test rig will be manufactured detailed discussions concerning the specifications are inevitable. In addition, training services of the local engineers how to work with the specific equipment is an essential part of the total delivery.

Available test rigs

- Domestic and commercial refrigerator test facilities, consisting of climate rooms with measurement and control equipment

- Compressor calorimeters for hermetic compressors

- Stirling cooler calorimeters

- Low voltage start test for hermetic compressors

- Lifetime test for hermetic compressors

- Different type of evaporator calorimeters

- Different type of condenser calorimeters

- Refrigerator analyzers

- Capillary / suction tube heat exchangers

- Taylor made test rigs.

For more information about Re/gent built test rigs or facilities, please feel free to contact Johan Wijnstekers (This email address is being protected from spambots. You need JavaScript enabled to view it.).

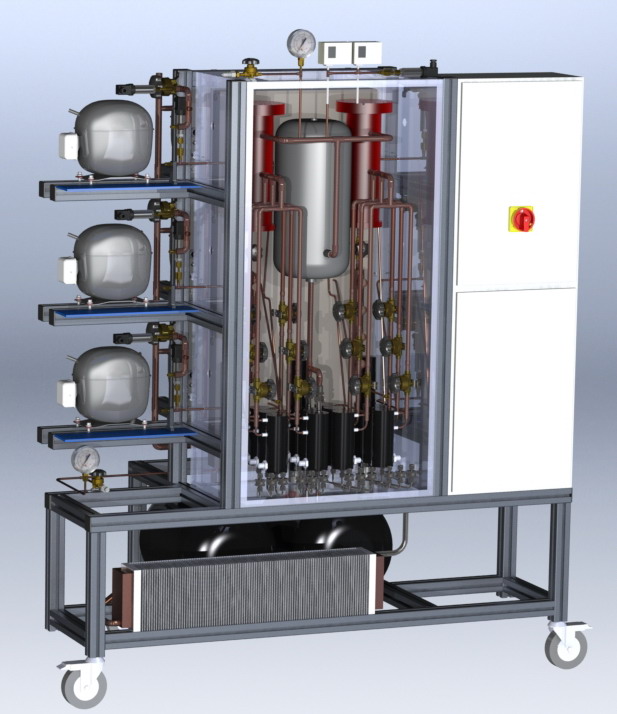

Fully automatic compressor calorimeters with cooling capacity ranges from 5 Watt to 10.000 Watt. Specific models available for domestic refrigerator compressors, commercial cooling unit compressors and (laundry-dryer) heat pump compressors.

Fully automatic compressor calorimeters with cooling capacity ranges from 5 Watt to 10.000 Watt. Specific models available for domestic refrigerator compressors, commercial cooling unit compressors and (laundry-dryer) heat pump compressors.

- 15 compressor positions.

- For each position it can be selected if a Wear, High temperature or On/off test is performed.

- Test is fully automatic, clear overview of ongoing tests and warnings in case of problems.

- Suitable for variable speed as well as for normal (single speed) compressors.

- Test conditions are flexible and can easily be programmed by the operator.

Fully automatically evacuates and starts a compressor running inside an acoustic test room. Automatically sequences over different test conditions as programmed by the user and gives a trigger signal for the acoustic measurement when obtaining stabil operation. Optionally also with vibration and pressure pulsation measurements and additional temperature measurements

Due to the use of stop-valves in refrigerators (valve after the condenser that closes when the compressor stops), compressors (usually variable speed) need to start up with a pressure difference between suction and discharge. With this set-up (for 12 compressors) On/off tests for such a start against unbalanced pressure can be performed. The pressures on suction and discharge can be set by the operator.

The Refrigerator Analyzer is used to determine the influence of many variables (e.g. refrigerant charge, capillary, control algorithm, fans etc.) on the performance and energy consumption of a refrigerator (refrigeration system).

System automatically performs start, stall and knocking noise tests while the compressor is exposed to a large field of suction and discharge pressures, suction gas temperatures, ambient temperatures, voltages and winding temperatures.