Introduction

The Refrigerator Analyzer is a system that is designed to measure the energy consumption of domestic refrigerator prototypes that are operating under specified conditions. For this purpose, the Refrigerator Analyzer can be connected to refrigerator prototypes (units under investigation) that are manufactured by the user. Different prototypes constitute different choices in variables like:

- Compressor, including compressor speed variation

- Evaporator

- Condenser

- Refrigerated cabinet (temperature zone) with corresponding heat load

- Capillary

- Refrigerant charge

- Condenser fan

- Evaporator fan

- Air flap (no frost appliances)

- On/off control algorithm of electrical components

After connection, the Refrigerator Analyzer is capable to control some of the prototype components and to measure relevant parameters. The refrigerator Analyzer comprises an automatic charging system in order to measure sequences of different refrigerant charging levels.

Control Functions of the Refrigerator Analyzer

- All fans can be turned on/off by the Refrigerator Analyzer. The supply voltage to these fans can be controlled between 6 and 15 VDC

- Both the heaters are controlled in a pulse width modulated way (on/off) in order to control the average heating capacity (in W) or to control the temperature within the temperature zones.

- The bi magnetic valves can be opened or closed in order to select the capillary tubes that are used

- The stop valves can be opened or closed

- The compressor can be turned on/off and its rotational speed can be set

- The charge valve can be opened or closed

- The system contains two free sockets. Power to these sockets can be switched on/off

- The air flap can be opened or closed

Measurement Functions of the Refrigerator Analyzer

- Power of the compressor, heaters, fans, free power sockets (voltage, current, power, frequency, power factor, integrated power) is measured.

- Pressure on suction and discharge sides (and inside the charge vessel)

- Differential pressure between arbitrary points inside the suction and discharge lines

- Refrigerator. Additionally, 1 thermocouple is used to measure the temperature inside the charge

- Refrigerant charge (using a pressure and temperature measurement of the gaseous refrigerant inside the vessel with known volume) is measured.

- Heat flux. A heat flux sensor can be placed on the outside of a temperature zone. The heat flux sensor uses the same connection as the thermocouples

- Vibration sensor. A 3-axis vibration sensor is included, results are presented in time and frequency domain

Basic Functioning of the Refrigerator Analyzer

The user is able to build a Refrigerator (prototype), connect relevant components to the Refrigerator Analyzer and fill the charge vessel with refrigerant. Subsequently a fully automatic measurement can be started:

1. Parameters will be set:

- The Refrigerator will be charged with a desired amount of refrigerant

- The capillary tubes are selected

- The compressor is controlled in order to obtain desired temperatures in the two temperature zones.

- The evaporator and condenser fans are controlled at a desired capacity

- If desired, an additional amount of heat load is applied to the temperature zones by controlling the electrical

2. The measurement will take place. The system waits for stabilization of the cabinet temperatures and power consumption and will subsequently save the data in a measurement file.

3. The system will set a new set point by modifying one of the following parameters:

- The capacity of one or more fans

- The selected capillary

- The refrigerant charge

- The compressor speed

- The use of the stop valve

Before the start of the tests, the user can specify which parameters have to be changed during the tests and can specify the desired set points for each parameter. At the end of the test it is possible to evaluate the Refrigerator power consumption as a function of for example the refrigerant charge, the capillary flow or the fan capacities applied. It is also possible to evaluate other values like the evaporation temperature, the condensation temperature, the compressor speed, etc. as a function of these parameters. Eventually the most optimum charge, capillary, fan capacity is determined for a certain set of components (evaporator, condenser, compressor etc.).

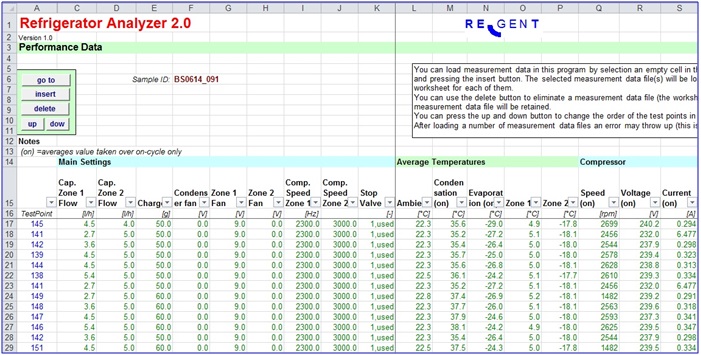

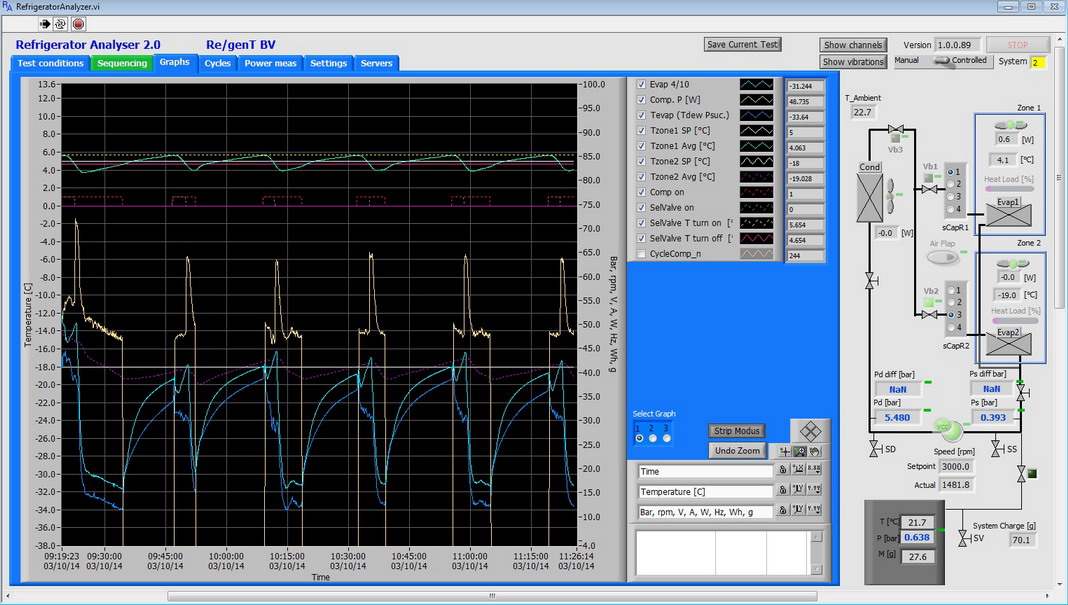

Example of the Refrigerator Analyzer control software

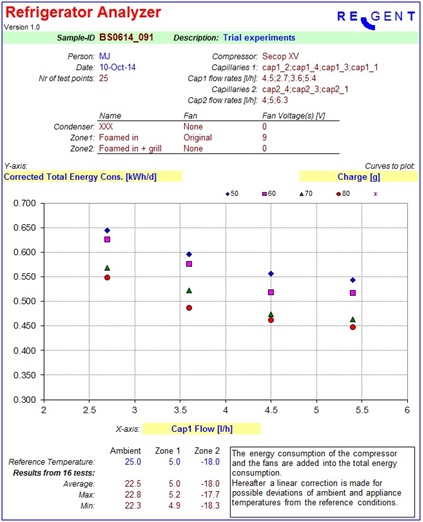

Example of the Refrigerator Analyzer evaluation software